Many will be bringing out the beef for a celebratory New Year’s feast (I’ve taken to steaming or grilling oysters on the BBQ).

Steaks and roasts are generally regarded as lower-risk products than hamburger because the meat is intact and E. coli, salmonella and friends can be killed by searing the outside, while the inside can be rare and microbiologically safe.

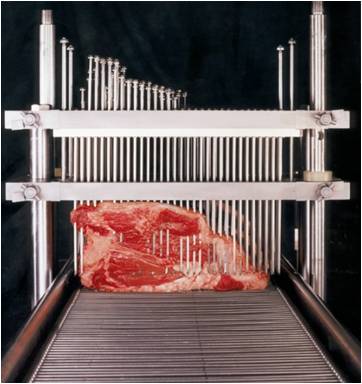

But what if needles pushed the E. coli on the outside of the steak to the inside? That’s what happens during blade or needle tenderization and the practice appears to be common although no .jpg) one is saying how common.

one is saying how common.

It was Christmas 2009, when an outbreak of E. coli O157:H7 that sickened at least 21 people was linked to blade tenderized or non-intact beef served at Appleby’s. There have been other outbreaks.

So what are consumers to do? Don’t expect labeling at retail any time soon. But two new research papers offer some insights.

Luchansky et al. build on previous work and conclude that E. coli O157:H7 and non-O157 STEC were spread throughout the interior of blade-tenderized steaks, and that when cooked on a gas grill, significant numbers of both pathogens were eliminated, but some survivors were recovered due, presumably, to uneven heating of the blade-tenderized steaks.

So what’s the policy and consumer recommendation for cooking steaks?

Wiegand et al. report that calculations based on D- and z-values obtained from isothermal ground beef studies increasingly overestimated destruction of E. coli O157:H7 in commercially cooked whole-muscle beef as process severity increased.

So what’s the policy and consumer recommendation for cooking roasts?

The abstracts are below.

Fate of Shiga toxin-producing O157:H7 and non-O157:H7 Escherichia coli cells within blade-tenderized beef steaks after cooking on a commercial open-flame gas grill

01.jan.12

Journal of Food Protection®, Volume 75, Number 1, January 2012 , pp. 62-70(9)

Luchansky, John B.; Porto-Fett, Anna C.S.; Shoyer, Bradley A.; Call, Jeffrey E.; Schlosser, Wayne; Shaw, William; Bauer, Nathan; Latimer, Andheejeong

Abstract:

We compared the fate of cells of both Shiga toxin-producing Escherichia coli O157:H7 (ECOH) and Shiga toxin-producing non-O157:H7 E. coli (STEC) in blade-tenderized steaks after tenderization and cooking on a gas grill. In phase I, beef subprimal cuts were inoculated on the lean side with about 5.5 log CFU/g of a five-strain mixture of ECOH or STEC and then passed once through a mechanical blade tenderizer with the lean side facing up. In each of two trials, 10 core samples were removed from each of two tenderized subprimals and cut into six consecutive segments starting from the inoculated side. Ten total cores also were obtained from two nontenderized (control) subprimals, but only segment 1 (the topmost segment) was sampled. The levels of ECOH and STEC recovered from segment 1 were about 6.0 and 5.3 log CFU/g, respectively, for the control subprimals and about 5.7 and 5.0 log CFU/g, respectively, for the tenderized subprimals. However, both ECOH and STEC behaved similarly in terms of translocation, and cells of both pathogen cocktails were recovered from all six segments of the cores obtained from tenderized subprimals, albeit at lower levels in segments 2 to 6 than those found in segment 1. In phase II, steaks (2.54 and 3.81 cm thick) cut from tenderized subprimals were subsequently cooked (three steaks per treatment) on a commercial open-flame gas grill to internal temperatures of 48.9, 54.4, 60.0, 65.6, and 71.1°C. Regardless of temperature or thickness, we observed 2.0- to 4.1-log and 1.5- to 4.5-log reductions in ECOH and STEC levels, respectively. Both ECOH and STEC behaved similarly in response to heat, in that cooking eliminated significant numbers of both pathogen types; however, some survivors were recovered due, presumably, to uneven heating of the blade-tenderized steaks.

Evaluating lethality of beef roast cooking treatments against Escherichia coli O157:H7

01.jan.12

Journal of Food Protection®, Volume 75, Number 1, January 2012 , pp. 48-61(14)

Wiegand, Kimberly M.; Ingham, Steven C.; Ingham, Barbara H.

http://www.ingentaconnect.com/content/iafp/jfp/2012/00000075/00000001/art00009

Abstract:

Added salt, seasonings, and phosphates, along with slow- and/or low-temperature cooking impart desirable characteristics to whole-muscle beef, but might enhance Escherichia coli O157:H7 survival. We investigated the effects of added salt, seasoning, and phosphates on E. coli O157:H7 thermotolerance in ground beef, compared E. coli O157:H7 thermotolerance in seasoned roasts and ground beef, and evaluated ground beef-derived D- and z-values for predicting destruction of E. coli O157:H7 in whole-muscle beef cooking. Inoculated seasoned and unseasoned ground beef was heated at constant temperatures of 54.4, 60.0, and 65.5°C to determine D- and z-values, and E. coli O157:H7 survival was monitored in seasoned ground beef during simulated slow cooking. Inoculated, seasoned whole-muscle beef roasts were slow cooked in a commercial smokehouse, and experimentally determined lethality was compared with predicted process lethality. Adding 5% seasoning significantly decreased E. coli O157:H7 thermotolerance in ground beef at 54.4°C, but not at 60 or 65.5°C. Under nonisothermal conditions, E. coliO157:H7 thermotolerance was greater in seasoned whole-muscle beef than in seasoned ground beef. Meeting U.S. Government (U.S. Department of Agriculture, Food Safety and Inspection Service, 1999, Appendix A) whole-muscle beef cooking guidance, which targets Salmonella destruction, would not ensure ≥6.5-log CFU/g reduction of E. coli O157:H7 in ground beef systems, but generally ensured $ 6.5-log CFU/g reduction of this pathogen in seasoned whole-muscle beef. Calculations based on D- and z-values obtained from isothermal ground beef studies increasingly overestimated destruction of E. coli O157:H7 in commercially cooked whole-muscle beef as process severity increased, with a regression line equation of observed reduction = 0.299 (predicted reduction) + 1.4373.

poop, is on the inside. With steaks and roasts, the thought has been that searing on the outside will take care of any poop bugs like E. coli and the inside is clean. But what if needles pushed the E. coli on the outside of the steak to the inside?

poop, is on the inside. With steaks and roasts, the thought has been that searing on the outside will take care of any poop bugs like E. coli and the inside is clean. But what if needles pushed the E. coli on the outside of the steak to the inside? cross-contamination, the bacterial counts recovered from the top layers of the first four pieces of meat decreased by approximately 0.5 log10 cfu/g after each tenderization. There was no decrease in the bacterial counts recovered from the top layers after the 4th tenderization. More tenderization studies were needed to quantitatively analyze the trend of lateral cross-contamination. However, it is evident that both vertical translocation and lateral cross-contamination can occur during mechanical tenderization of meat.

cross-contamination, the bacterial counts recovered from the top layers of the first four pieces of meat decreased by approximately 0.5 log10 cfu/g after each tenderization. There was no decrease in the bacterial counts recovered from the top layers after the 4th tenderization. More tenderization studies were needed to quantitatively analyze the trend of lateral cross-contamination. However, it is evident that both vertical translocation and lateral cross-contamination can occur during mechanical tenderization of meat. use

use  in the roasting pan to limit bug flow in the kitchen. Being prepped and having everything near the sink helps. Be the bug.

in the roasting pan to limit bug flow in the kitchen. Being prepped and having everything near the sink helps. Be the bug.