The bartender was riveted. So was the waitress. My requests for a beverage

on a quiet Tuesday afternoon in Kansas City in 1998 would have to wait until

commercial. Such was the power of Oprah.

commercial. Such was the power of Oprah.

That’s Oprah Winfrey – actress cum talk show diva – who today did a segment on beef production as part of her go-vegan spiel.

The results were far more conciliatory than earlier meat outings on Oprah, and the credit goes to Cargill, who opened one of their Colorado processing plants to Oprah’s cameras and rather than resort to a corporate spokesthingy, featured a surprisingly effective Nicole Johnson-Hoffman, the plant’s general manager.

Things didn’t go so well for the meat folks in 1996.

On March 29, 1996, nine days after the U.K. officially linked bovine spongiform encephalopathy, or BSE, with a new human disease, the U.S. Department of Agriculture and the U.S. Food and Drug Administration announced they were  expediting regulations prohibiting ruminant protein in ruminant feeds, boosting

expediting regulations prohibiting ruminant protein in ruminant feeds, boosting

surveillance and expanding research.

The same day, several producer groups, including the U.S. National Cattlemen’s Beef Association (NCBA), issued a statement supporting the moves and instituted a voluntary ban on ruminant protein in ruminant feed. Draft legislation was published in January 1997 and enacted into law later that year.

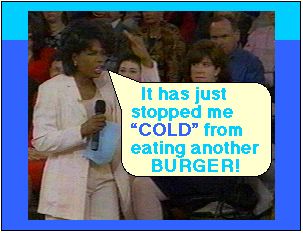

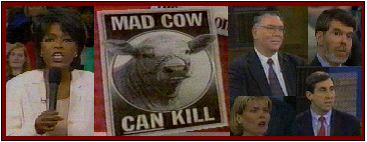

Then came Oprah. On April 16, 1996, Oprah announced during a show on food safety and mad cow disease she would stop eating hamburgers because of fears over BSE and that she was shocked after a guest said meat and bone meal made from cattle was routinely fed to other cattle to boost their meat and milk production.

The camera showed members of the studio audience gasping in surprise as vegetarian activist Howard Lyman explained how cattle parts and downer cattle (downer is the generic term used to describe cattle who can simply no  longer stand) were rendered and fed to other cattle, and that BSE could make AIDS look like a common cold. The chief scientist for the U.S. National Cattleman’s Beef Association, rather than stressing the risk management actions that had been taken, was left arguing that cows were not vegetarians because they drank milk.

longer stand) were rendered and fed to other cattle, and that BSE could make AIDS look like a common cold. The chief scientist for the U.S. National Cattleman’s Beef Association, rather than stressing the risk management actions that had been taken, was left arguing that cows were not vegetarians because they drank milk.

Today’s broadcast was different. Foodie journalist Michael Pollan wants people to know where their food comes from; Cargill obliged.

“Lisa Ling travels to Colorado, where Cargill, the biggest producer of ground beef in the world, gives her a rare inside look at how our meat is made.

“Upon arrival, the cattle are held in pens for two hours to calm them before they’re sent to be slaughtered. Each cow is then shot in the head with a bolt, which renders it insensible to pain. The cow’s artery is then cut, and about two minutes later, it dies from blood loss. After the animal’s death, the body is  immediately washed, the skin is removed, and within minutes, the workers also remove the hooves, the hide and the head. The carcass is then moved to a giant cooler, where it stays for up to two days. After it’s been inspected and graded, it’s packaged, loaded on trucks and soon ends up in our local restaurants and stores.

immediately washed, the skin is removed, and within minutes, the workers also remove the hooves, the hide and the head. The carcass is then moved to a giant cooler, where it stays for up to two days. After it’s been inspected and graded, it’s packaged, loaded on trucks and soon ends up in our local restaurants and stores.

“Nicole says she was happy to have Lisa at the plant, because she thinks people should know where their food is coming from. ‘I would not ridicule people who believe that you shouldn’t eat animals, but I would say that we are  committed to doing it right. And I believe that when animals are handled with dignity and harvested carefully, that’s the natural order of things,’ says Nicole.

committed to doing it right. And I believe that when animals are handled with dignity and harvested carefully, that’s the natural order of things,’ says Nicole.

Whether you eat meat or not, Nicole thinks everyone who’s interested in the American food system can work together to create better results. ‘I think we’re all on the same path trying to figure out the right way to get to good health for our families and environmental sustainability and humane treatment,’ she says. ‘We’ll find a better result together, even if we have perhaps different perspectives or different beliefs.’”

The slaughterhouse portion of the video is available at:=

http://www.oprah.com/oprahshow/Inside-a-Slaughterhouse-Video/topic/oprahshow

.jpg) Saturday retailers are willing to work with suppliers on reasonable cost increases related to improved meat product safety.

Saturday retailers are willing to work with suppliers on reasonable cost increases related to improved meat product safety..jpg) than those issued by the government, and the third-party assurances carry weight in the market.

than those issued by the government, and the third-party assurances carry weight in the market.

commercial. Such was the power of Oprah.

commercial. Such was the power of Oprah. expediting regulations prohibiting ruminant protein in ruminant feeds, boosting

expediting regulations prohibiting ruminant protein in ruminant feeds, boosting longer stand) were rendered and fed to other cattle, and that BSE could make AIDS look like a common cold. The chief scientist for the U.S. National Cattleman’s Beef Association, rather than stressing the risk management actions that had been taken, was left arguing that cows were not vegetarians because they drank milk.

longer stand) were rendered and fed to other cattle, and that BSE could make AIDS look like a common cold. The chief scientist for the U.S. National Cattleman’s Beef Association, rather than stressing the risk management actions that had been taken, was left arguing that cows were not vegetarians because they drank milk. immediately washed, the skin is removed, and within minutes, the workers also remove the hooves, the hide and the head. The carcass is then moved to a giant cooler, where it stays for up to two days. After it’s been inspected and graded, it’s packaged, loaded on trucks and soon ends up in our local restaurants and stores.

immediately washed, the skin is removed, and within minutes, the workers also remove the hooves, the hide and the head. The carcass is then moved to a giant cooler, where it stays for up to two days. After it’s been inspected and graded, it’s packaged, loaded on trucks and soon ends up in our local restaurants and stores. committed to doing it right. And I believe that when animals are handled with dignity and harvested carefully, that’s the natural order of things,’ says Nicole.

committed to doing it right. And I believe that when animals are handled with dignity and harvested carefully, that’s the natural order of things,’ says Nicole.