The N.Y. Times has noticed the growing number of recalls linked to Listeria-positive frozen produce packed by CRF Frozen Foods in Pasco, Wash., but offers little perspective on why.

Zero-tolerance is not discussed. Neither is the test-and-hold approach used by many frozen-produce packagers. And of particular note: During our tour of Ontario processing vegetable growers and processors 15 years ago, Chapman and I were told that almost all processing vegetables are blanched – not so much for food safety but for quality – except onions.

Zero-tolerance is not discussed. Neither is the test-and-hold approach used by many frozen-produce packagers. And of particular note: During our tour of Ontario processing vegetable growers and processors 15 years ago, Chapman and I were told that almost all processing vegetables are blanched – not so much for food safety but for quality – except onions.

Back to the onions at the end.

Brittany Behm, a spokeswoman for the U.S. Centers for Disease Control and Prevention, told the Times the scale of the recall reflects the severity of the outbreak of the illness, Listeria, and of concerns about how the contaminated food might have “trickled down” into other products.

The processing plant, has voluntarily recalled more than 350 frozen foods — including carrots, onions, peaches and strawberries — that were sold in all 50 states and Canada and Mexico, and the EU. The recall began on April 23, with 11 frozen vegetables, but was significantly expanded on May 2.

Eight people sickened with the bacterium Listeria monocytogenes have been confirmed since 2013 — six in California and one each in Maryland and Washington, Ms. Behm said. All of the cases, involving patients 56 to 86 years old, resulted in hospitalizations.

The two people from Maryland and Washington died, but the authorities did not directly attribute their deaths to Listeria because they may have already had weakened immune systems or other illnesses, Ms. Behm said.

It was not clear how many packages were affected by the recall. A spokesman for the company, Gene Grabowski, did not respond to a phone call on Friday. He told The Associated Press that the CRF plant closed two weeks ago and that the company was trying to pinpoint the source of the contamination.

“Unquestionably, this is a lot of product. … It reflects the severity of listeria as an illness, the long duration of illnesses and the outbreak and the long shelf life of the products,” said Matthew Wise, who leads the outbreak response team at the federal Centers for Disease Control and Prevention.

“Unquestionably, this is a lot of product. … It reflects the severity of listeria as an illness, the long duration of illnesses and the outbreak and the long shelf life of the products,” said Matthew Wise, who leads the outbreak response team at the federal Centers for Disease Control and Prevention.

On May 14, 2016, Food Safety News reported that staff from the U.S. Food and Drug Administration inspected the CRF Frozen Foods LLC plant in Pasco, WA, from March 14-17.

The company stopped production at the plant April 25 after being notified by federal officials that frozen vegetables produced there had been linked by genetic testing to several people who had infections from Listeria monocytogenes.

The two-page FDA inspection report includes boilerplate citations of applicable sections of the federal Food, Drug and Cosmetic Act on its second page. The first page includes hand-written observations documenting:

a damaged plastic shovel used for food contact tasks;

chipping, cracking and missing pieces of plastic on food contact portions of equipment on the onion production line;

a plastic conveyor belt with missing plastic pieces on at least five legs that are in direct contact with onions;

utility knives used for trimming bad spots off onions that had initials etched on their blades; and

blue tape being used as a temporary repair on a cracked metal plate above a consumer pack line that was repacking product for export at the time of the inspection.

All of the examples cited by inspectors are cause of concern for the same reason — they mean it’s impossible to adequately clean the equipment that is in direct contact with food being produced.

“The materials and workmanship of equipment and utensils does not allow proper cleaning and maintenance,” according to the report.

“Investigations are ongoing to determine if food sources used to manufacture CRF Frozen Foods products could explain some of the illnesses,” FDA reported in its most recent update May 4.

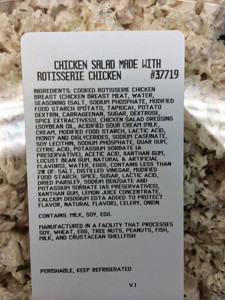

One of those “food sources” could be onions from Oregon Potato Co., also located in Pasco, WA.

“March 2016 environmental samples collected by FDA from Oregon Potato Company, located in Pasco, WA, were found to be closely related genetically to seven of the isolates of ill people associated with this outbreak,” the FDA reported.

“Based on this information, Oregon Potato Company voluntarily recalled wholesale onion products, which led to subsequent downstream customer recalls, one of which publicly disclosed Oregon Potato Company as its product source.”

I’m still feeling good about that deal. And an excellent addition to tonight’s duck stew.

I’m still feeling good about that deal. And an excellent addition to tonight’s duck stew..jpg) contaminated with E. coli, says the website for law firm Sutts, Strosberg LLP.

contaminated with E. coli, says the website for law firm Sutts, Strosberg LLP.(1).jpg) Apparently it was the

Apparently it was the