We had some dinner at our favorite local haunt last night, partly because going out tonight on St. Patrick’s Day with a 2-year-old may be dumb.

I had been reading about a New Mexico woman who says a sewing needle pierced her tongue after she bit into a plate of ribs and mashed potatoes at a Chili’s restaurant and thought, I wouldn’t want to run a restaurant. Too much vulnerability.

The NM woman says she pulled a needle about 2-inches long from her mouth at the Chili’s in Farmington last July. The 23-year-old says Chili’s employees quickly  took the needle, and a manager refused to give it back when she and her husband returned to request it for testing.

took the needle, and a manager refused to give it back when she and her husband returned to request it for testing.

Consumers, if you want to pursue a legitimate claim, do not give the food or item to the restaurant – take it to the local health unit.

Restaurant owners – don’t hesitate to call on the forensic expertise of the state; they often have the expertise to separate accident from extortion.

The NM woman further said she’s suing the Chili’s chain because the company took 52 days to send the needle to a lab. She says she’s since tested clean for HIV, hepatitis and other possible infections, but had to stop nursing her baby in the meantime.

Representatives of Chili’s Restaurant and Grill and Chili’s Inc. declined to comment.

Ron Ruggless writing in Nation’s Restaurant News, says that restaurateurs who find themselves with customers claiming to have discovered foreign objects in their food face a fine line between hospitable communications and legal cautions.

A public relations professional who asked not to be identified because many clients are restaurant chains, said any foodservice operation can benefit from training staff to deal with complaints immediately as they arise, as well as consulting legal counsel.

Michael Heenan, a corporate crisis consultant and owner of Heenan Communications in Sacramento, Calif., said,

“What I tell clients is that in the midst of a crisis, when everyone’s anxiety is high and everyone’s defensiveness is high and there are personal hurt feelings about the safety of the product or the reputation of your company, that is not the time to find out what the dynamic is within your company.”

For independent operators without a corporate infrastructure, Heenan said the job is much more sensitive. “If you are doing it more or less on your own,” he said, “it’s asking a lot. It’s a very stressful environment.”

“The usual mistakes are of the brittle, defensive and unsympathetic nature. If you do nothing else as an individual owner, remember that you must put aside your anger and remember how poorly that looks to the rest of the world. They need to see how concerned you are.”

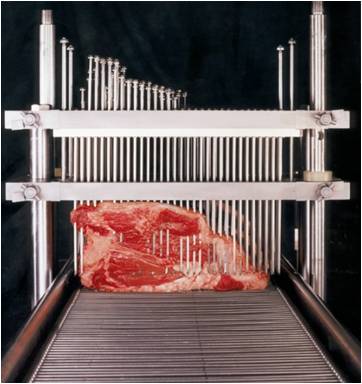

poop, is on the inside. With steaks and roasts, the thought has been that searing on the outside will take care of any poop bugs like E. coli and the inside is clean. But what if needles pushed the E. coli on the outside of the steak to the inside?

poop, is on the inside. With steaks and roasts, the thought has been that searing on the outside will take care of any poop bugs like E. coli and the inside is clean. But what if needles pushed the E. coli on the outside of the steak to the inside? cross-contamination, the bacterial counts recovered from the top layers of the first four pieces of meat decreased by approximately 0.5 log10 cfu/g after each tenderization. There was no decrease in the bacterial counts recovered from the top layers after the 4th tenderization. More tenderization studies were needed to quantitatively analyze the trend of lateral cross-contamination. However, it is evident that both vertical translocation and lateral cross-contamination can occur during mechanical tenderization of meat.

cross-contamination, the bacterial counts recovered from the top layers of the first four pieces of meat decreased by approximately 0.5 log10 cfu/g after each tenderization. There was no decrease in the bacterial counts recovered from the top layers after the 4th tenderization. More tenderization studies were needed to quantitatively analyze the trend of lateral cross-contamination. However, it is evident that both vertical translocation and lateral cross-contamination can occur during mechanical tenderization of meat. police for the second time in a month over what appears to be food tampering.

police for the second time in a month over what appears to be food tampering. ground up – the outside, which can be laden with poop, is on the inside. With steaks, the thought has been that searing on the outside will take care of any poop bugs like E. coli and the inside is clean. But what if needles pushed the E. coli on the outside of the steak to the inside?

ground up – the outside, which can be laden with poop, is on the inside. With steaks, the thought has been that searing on the outside will take care of any poop bugs like E. coli and the inside is clean. But what if needles pushed the E. coli on the outside of the steak to the inside? That was 1999. I don’t see any such intact or non-intact label when I go to the grocery store. Restaurants remain a faith-based food safety institution. And the issue has rarely risen to the level of public discussion.

That was 1999. I don’t see any such intact or non-intact label when I go to the grocery store. Restaurants remain a faith-based food safety institution. And the issue has rarely risen to the level of public discussion.