I spent the last two hours doing my annual talk and chat session with summer public health students, invoking in them the capacity to care; public health  ain’t glamorous, but it matters.

ain’t glamorous, but it matters.

Contrary to what Kansas State University admin types may think, the stagecoaches manage to run through Brisbane at 1 a.m.

Somehow I also managed to comment on needle tenderized beef, while not physically in Manhattan (the Kansas version) even though I’ve been there the majority of the last four months.

And I made a hockey analogy.

I even had a guy visit me at the house yesterday to talk food safety, and he asked me to show him a hockey puck.

I did.

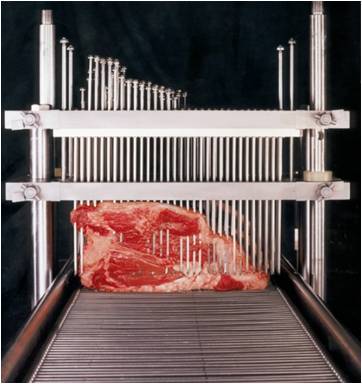

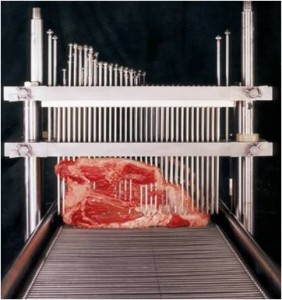

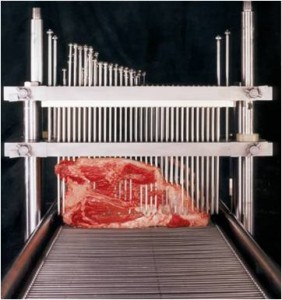

Elizabeth Weise writes in USA Today today that after years of food-safety concerns and at least five outbreaks of illness, the U.S. Department of Agriculture is proposing that mechanically tenderized meat — 26% of all the beef sold in the USA — be labeled as such and that labels include cooking instructions.

Tenderizing meat mechanically involves forcing hundreds of tiny blades or needles through it to break up muscle fibers and make it more tender.

Unfortunately, it can also drive pathogens that might be on the surface, such as E. coli O157:H7, deep into the cut’s interior, where cooking may not kill them. According to the Centers for Disease Control and Prevention, there have  been five E. coli outbreaks attributed to mechanically tenderized beef, sickening 174 people. Four died.

been five E. coli outbreaks attributed to mechanically tenderized beef, sickening 174 people. Four died.

It’s impossible to tell just by looking that a cut of meat has undergone mechanical tenderization, said USDA Undersecretary Elisabeth Hagen.

“When people buy cube steak, you see the marks where the machinery has cubed up the steak,” Hagen said. “When people buy ground beef, they know they’re getting ground product. But when people order this product, they don’t know. And certainly, when people are ordering in a restaurant, they don’t know they’re ordering this product.”

She added, “A lot of people want a medium-rare steak. But if folks knew that the steak they’re buying might not be what they think it is, and might be in a higher risk category,” they might want it well done.

Some stores do label the product. Costco labels mechanically tenderized beef it sells as “blade tenderized.”

Until now, the USDA hadn’t required producers to label mechanically tenderized meat so consumers know what they’re buying. The new rules, to be announced Thursday, would require that mechanically tenderized products be labeled. The labels would include cooking instructions.

Hagen said mechanically tenderized meat should be cooked to an internal temperature of at least 145 degrees, then allowed to sit for at least three  minutes after it is taken off the heat to insure any potential pathogens are killed.

minutes after it is taken off the heat to insure any potential pathogens are killed.

Canada has rules in the works to require labeling of mechanically tenderized meat. Last October, an outbreak of E. coli O157:H7 linked to meat processor XL Foods sickened 18 people and led to the country’s largest beef recall, almost 2.5 million pounds of meat. Some of it was mechanically tenderized.

Some food-safety specialists aren’t sure labeling would make much difference.

“We can’t get people to use thermometers on steaks. Why would they do it for needle-tenderized meat?” said Doug Powell, a professor of food safety at Kansas State University in Manhattan, Kan.

Cooking blade-tenderized meat to 145 degrees, the temperature required to kill E. coli, would “turn it into a hockey puck,” Powell said. “Why would someone pay the premium for steak or roast and then turn it into a hockey puck?”

rare beefburgers, rejecting claims they were a health risk.

rare beefburgers, rejecting claims they were a health risk.