It’s an important day for food safety types because new research shows E. coli O157:H7 can enter beef cuts like steak during mechanical or blade or needle tenderization, as it’s called.

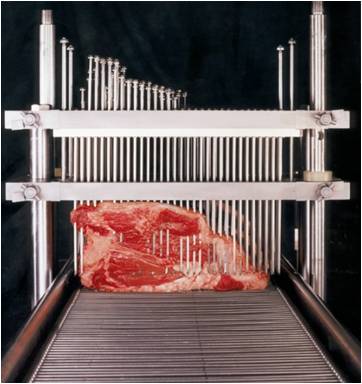

The idea is that small needles are inserted into steak to inject tenderizers. All hamburger should be cooked to a thermometer-verified 160F because it’s all ground up – the outside, which can be laden with  poop, is on the inside. With steaks and roasts, the thought has been that searing on the outside will take care of any poop bugs like E. coli and the inside is clean. But what if needles pushed the E. coli on the outside of the steak to the inside?

poop, is on the inside. With steaks and roasts, the thought has been that searing on the outside will take care of any poop bugs like E. coli and the inside is clean. But what if needles pushed the E. coli on the outside of the steak to the inside?

Previous work has shown similar results, and the new research in the Journal of Food Safety confirms that E. coli O157:H7 can enter the interior of beef cuts like steaks during the tenderization process. The new work does not assess whether cooking on a grill can kill off the internalized bacteria but does refocus attention on a lingering food safety issue, almost one year after an E. coli O157:H7 outbreak in needle tenderized beef sickened at least 21 people in 16 states.

Luchansky et al. wrote in the July 2009 JFP that based on inoculation studies, cooking on a commercial gas grill is effective at eliminating relatively low levels of the pathogen that may be distributed throughout a blade-tenderized steak.

Quantitative analysis of vertical translocation and lateral cross-contamination of Escherichia coli O157:H7 during mechanical tenderization of beef

30.nov.10

Journal of Food Safety

Lihan Huang, Shiowshuh Sheen

http://onlinelibrary.wiley.com/doi/10.1111/j.1745-4565.2010.00273.x/abstract

ABSTRACT

Quantitative vertical translocation and lateral cross-contamination of Escherichia coli O157:H7 during mechanical tenderization of beef meat were investigated using a restaurant-style meat tenderizer, which was first used to tenderize a surface-inoculated sample, and then an additional four uninoculated samples. It was observed that the vertically translocated bacteria (in log10 cfu/g) was directly proportional to the logarithm of the tenderization depth, with an average translocation coefficient of 3.14 ± 0.66 log10 cfu/g per log10 mm of depth. For lateral  cross-contamination, the bacterial counts recovered from the top layers of the first four pieces of meat decreased by approximately 0.5 log10 cfu/g after each tenderization. There was no decrease in the bacterial counts recovered from the top layers after the 4th tenderization. More tenderization studies were needed to quantitatively analyze the trend of lateral cross-contamination. However, it is evident that both vertical translocation and lateral cross-contamination can occur during mechanical tenderization of meat.

cross-contamination, the bacterial counts recovered from the top layers of the first four pieces of meat decreased by approximately 0.5 log10 cfu/g after each tenderization. There was no decrease in the bacterial counts recovered from the top layers after the 4th tenderization. More tenderization studies were needed to quantitatively analyze the trend of lateral cross-contamination. However, it is evident that both vertical translocation and lateral cross-contamination can occur during mechanical tenderization of meat.

PRACTICAL APPLICATIONS

Foodborne illnesses caused by consumption of undercooked non-intact beef meats contaminated with Escherichia coli O157:H7 are an emerging public food safety concern as evidenced by a major outbreak recently. This study investigated both vertical translocation and lateral cross-contamination of E. coli O157:H7 during mechanical tenderization of beef. The results from this work can aid quantitative assessment of risks caused by non-intact beef meats.