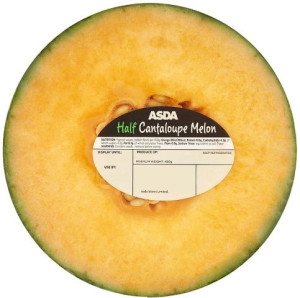

Everywhere I go in Brisbane, I see cut cantaloupe.

Rock melon as the locals call it.

Rock melon as the locals call it.

From the biggest retail megalomarts to the local fruit and veg., aging cantaloupes are cut in half, wrapped in cellophane, stored at room temperature and sold at a slight discount.

This is a Salmonella growth factory.

The practice is shameful, and for every corporate food safety thingy out there who says with a straight face, food safety is our top priority, you’re full of it.

I’m looking at you, Coles and Woolworths (which control the retail grocery market in Australia).

I’m told the melon-in-half practice is prevalent in California, Florida, and pretty much everywhere.

The thing with produce – especially the ones in repeated outbreaks like cantaloupe, leafy greens and tomatoes – is that once it is cut in any way, the cut provides a growth medium for any existing microorganisms. Storing at room temperature sets fire to the flame, which is why the cold-chain is so important for cut produce.

Friend of barfblog Schaffner just can’t stop writing papers, which is good, because food safety needs more evidence and less faith.

Abstract below.

Development and validation of a mathematical model for growth of pathogens in cut melons.

Journal of Food Protection, Number 6, June 2013, pp. 928-1108 , pp. 953-958(6)

Li, Di; Friedrich, Loretta M.; Danyluk, Michelle D.; Harris, Linda J.; Schaffner, Donald W.

Many outbreaks of foodborne illness associated with the consumption of fresh-cut melons have been reported. The objective of our research was to develop a mathematical model that predicts the growth rate of Salmonella on  fresh-cut cantaloupe over a range of storage temperatures and to validate that model by using Salmonella and Escherichia coli O157:H7 on cantaloupe, honeydew, and watermelon, using both new data and data from the published studies. The growth of Salmonella on honeydew and watermelon and E. coli O157:H7 on cantaloupe, honeydew, and watermelon was monitored at temperatures of 4 to 25°C. The Ratkowsky (or square-root model) was used to describe Salmonella growth on cantaloupe as a function of storage temperature. Our results show that the levels of Salmonella on fresh-cut cantaloupe with an initial load of 3 log CFU/g can reach over 7 log CFU/g at 25°C within 24 h. No growth was observed at 4°C. A linear correlation was observed between the square root of Salmonella growth rate and temperature, such that √growth rate = 0.026 × (T – 5.613), R2 = 0.9779. The model was generally suitable for predicting the growth of both Salmonella and E. coli O157:H7 on cantaloupe, honeydew, and watermelon, for both new data and data from the published literature. When compared with existing models for growth of Salmonella, the new model predicts a theoretic minimum growth temperature similar to the ComBase Predictive Models and Pathogen Modeling Program models but lower than other food-specific models. The ComBase Prediction Models results are very similar to the model developed in this study. Our research confirms that Salmonella can grow quickly and reach high concentrations when cut cantaloupe is stored at ambient temperatures, without visual signs of spoilage. Our model provides a fast and cost-effective method to estimate the effects of storage temperature on fresh-cut melon safety and could also be used in subsequent quantitative microbial risk assessments.

fresh-cut cantaloupe over a range of storage temperatures and to validate that model by using Salmonella and Escherichia coli O157:H7 on cantaloupe, honeydew, and watermelon, using both new data and data from the published studies. The growth of Salmonella on honeydew and watermelon and E. coli O157:H7 on cantaloupe, honeydew, and watermelon was monitored at temperatures of 4 to 25°C. The Ratkowsky (or square-root model) was used to describe Salmonella growth on cantaloupe as a function of storage temperature. Our results show that the levels of Salmonella on fresh-cut cantaloupe with an initial load of 3 log CFU/g can reach over 7 log CFU/g at 25°C within 24 h. No growth was observed at 4°C. A linear correlation was observed between the square root of Salmonella growth rate and temperature, such that √growth rate = 0.026 × (T – 5.613), R2 = 0.9779. The model was generally suitable for predicting the growth of both Salmonella and E. coli O157:H7 on cantaloupe, honeydew, and watermelon, for both new data and data from the published literature. When compared with existing models for growth of Salmonella, the new model predicts a theoretic minimum growth temperature similar to the ComBase Predictive Models and Pathogen Modeling Program models but lower than other food-specific models. The ComBase Prediction Models results are very similar to the model developed in this study. Our research confirms that Salmonella can grow quickly and reach high concentrations when cut cantaloupe is stored at ambient temperatures, without visual signs of spoilage. Our model provides a fast and cost-effective method to estimate the effects of storage temperature on fresh-cut melon safety and could also be used in subsequent quantitative microbial risk assessments.