Poor hygiene when handling food is a major cause of foodborne illness. To investigate whether hygiene practices visible in television cooking shows influence viewers’ kitchen hygiene, a study on the adoption of demonstrated hygiene behavior was conducted under controlled, experimental conditions.

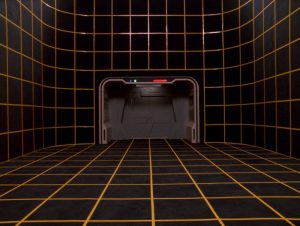

In a study ostensibly on cooking by following recipes participants (n = 65) were randomly assigned to one of three conditions, in which they watched a cooking video that differed only with regard to the hygiene behavior of the chef. In condition 1, the chef engaged in poor hygiene practices while preparing the dish, in condition 2 the chef’s hygiene behavior was exemplary and in condition 3, the chef’s hygiene behavior was not visible (control condition). After watching the video, participants were instructed to cook the recipe individually in the fully equipped laboratory kitchen. Cooking sessions were videotaped and experimenters blind to condition coded hygiene lapses committed by participants.

In a study ostensibly on cooking by following recipes participants (n = 65) were randomly assigned to one of three conditions, in which they watched a cooking video that differed only with regard to the hygiene behavior of the chef. In condition 1, the chef engaged in poor hygiene practices while preparing the dish, in condition 2 the chef’s hygiene behavior was exemplary and in condition 3, the chef’s hygiene behavior was not visible (control condition). After watching the video, participants were instructed to cook the recipe individually in the fully equipped laboratory kitchen. Cooking sessions were videotaped and experimenters blind to condition coded hygiene lapses committed by participants.

The level of kitchen hygiene displayed in the cooking video significantly affected hygiene practices of participants cooking the recipe. Participants who had watched the cooking video with correct hygiene practices committed significantly fewer hygiene lapses than those who had watched the video with poor hygiene practices. From a risk communication perspective, TV cooking shows are well placed to convey knowledge of essential hygiene practices during food preparation to a broad audience. To facilitate behavioral change toward safer food‐handling practices among viewers, visibly performing correct hygiene practices in cooking shows is a promising strategy.

Kitchen hygiene in the spotlight: How cooking shows influence viewers’ hygiene practices

Risk Analysis

Severine Koch, Mark Lohmann, Jasmin Geppert, Rainer Stamminger, Astrid Epp, Gaby‐Fleur Böl

The conversation goes to pizza and COVID-19 (Australian and Jersey), Thanksgiving plans (or lack thereof) and eating just black licorice as nutrient source. The episode ends with a discussion about number and size of COVID-19 clusters of in various food settings.

The conversation goes to pizza and COVID-19 (Australian and Jersey), Thanksgiving plans (or lack thereof) and eating just black licorice as nutrient source. The episode ends with a discussion about number and size of COVID-19 clusters of in various food settings.