It’s not a headline so Betteridge’s Law isn’t in play.

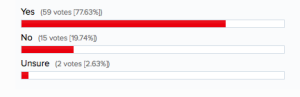

A food safety friend shared this poll from the International Food Safety & Quality Network’s page.

The best comment on the forum is:

This happens all the time. A company ignores food safety for 9 or 10 months and then there is a big push to get everything in line prior to the audit. Once the audit results are in, back to business as usual. It’s sad, but true – in many cases management simply sees a certification as a marketing tool.

Audits don’t really measure food safety culture.

Or as we wrote in 2013, Audits and inspections are never enough: A critique to enhance food safety

Powell, D., Erdozain, M., Dodd, C. Morley, K., Costa, R. and Chapman, B. 2013.

Food Control. 30: 686-691.

Internal and external food safety audits are conducted to assess the safety and quality of food including on-farm production, manufacturing practices, sanitation, and hygiene. Some auditors are direct stakeholders that are employed by food establishments to conduct internal audits, while other auditors may represent the interests of a second-party purchaser or a third-party auditing agency. Some buyers conduct their own audits or additional testing, while some buyers trust the results of third-party audits or inspections. Third-party auditors, however, use various food safety audit standards and most do not have a vested interest in the products being sold. Audits are conducted under a proprietary standard, while food safety inspections are generally conducted within a legal framework. There have been many foodborne illness outbreaks linked to food processors that have passed third-party audits and inspections, raising questions about the utility of both. Supporters argue third-party audits are a way to ensure food safety in an era of dwindling economic resources. Critics contend that while external audits and inspections can be a valuable tool to help ensure safe food, such activities represent only a snapshot in time. This paper identifies limitations of food safety inspections and audits and provides recommendations for strengthening the system, based on developing a strong food safety culture, including risk-based verification steps, throughout the food safety system.