Still no mention of thermometers which makes this Agency not so-science based.

The Food Standards Agency reports results for the second quarter of testing, from October to December 2015, continue to show a decrease in the number of birds with the highest level of contamination from the same months last year. These most heavily contaminated birds, carrying more than 1,000 colony forming units per gram (cfu/g), are the focus of the current target agreed by industry, which is equivalent to no more than 7% of chickens at retail having the highest levels of contamination. Research has shown that reducing the proportion of birds in this category will have the biggest positive impact on public health.

The Food Standards Agency reports results for the second quarter of testing, from October to December 2015, continue to show a decrease in the number of birds with the highest level of contamination from the same months last year. These most heavily contaminated birds, carrying more than 1,000 colony forming units per gram (cfu/g), are the focus of the current target agreed by industry, which is equivalent to no more than 7% of chickens at retail having the highest levels of contamination. Research has shown that reducing the proportion of birds in this category will have the biggest positive impact on public health.

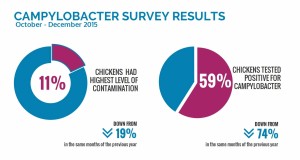

The latest data show 11% of chickens tested positive for the highest level of contamination, down from 19% in October to December 2014. Campylobacter was present on 59% of chicken samples, down from 74% in the same months of the previous year.

In this second quarter of the FSA’s second survey, 966 samples of fresh whole chilled UK-produced chickens and packaging have been tested. The chickens were bought from large UK retail outlets and smaller independent stores and butchers. The survey commenced sampling in July 2015.

The data continue to show an improvement from the previous year. Interventions, including improved biosecurity, SonoSteam, and the trimming of neck skins, introduced by some retailers to reduce levels of campylobacter, may be helping to deliver the improved results. The trimming of the neck skin, the most highly contaminated skin area, means chickens are carrying less campylobacter. The results of this intervention, while making chickens safer, mean comparisons to the first year’s survey may potentially be more difficult in future quarters as most samples from the previous year will have analysed more neck skin. The FSA will review the impact of this successful intervention to ensure the survey results remain robust.

The FSA has been testing chickens for campylobacter since February 2014 and publishing the results as part of its campaign to bring together the whole chicken supply chain to tackle the problem. Campylobacter is the most common cause of food poisoning in the UK, making an estimated 280,000 people ill every year.

The FSA is pressing the industry to play its part in reducing the levels of campylobacter contamination at each production stage to as low a level as possible before raw chicken reaches the consumer. Chicken is safe as long as consumers follow good kitchen practice:

The FSA is pressing the industry to play its part in reducing the levels of campylobacter contamination at each production stage to as low a level as possible before raw chicken reaches the consumer. Chicken is safe as long as consumers follow good kitchen practice:

Cover and chill raw chicken: Cover raw chicken and store on the bottom shelf of the fridge so juices cannot drip on to other foods and contaminate them with food poisoning bacteria such as Campylobacter.

Don’t wash raw chicken: Cooking will kill any bacteria present, including Campylobacter, while washing chicken can spread germs by splashing.

Wash hands and used utensils: Thoroughly wash and clean all utensils, chopping boards and surfaces used to prepare raw chicken. Wash hands thoroughly with soap and warm water, after handling raw chicken. This helps stop the spread of Campylobacter by avoiding cross contamination.

Cook chicken thoroughly: Make sure chicken is steaming hot all the way through before serving. Cut in to the thickest part of the meat and check that it is steaming hot with no pink meat and that the juices run clear.

Year 2 of a UK-wide survey of campylobacter contamination on fresh chickens at retail (July 2015 to July 2016)

This 12-month survey investigates the prevalence and levels of campylobacter contamination on fresh whole chilled chickens and their packaging. The survey aims to examine more than 4,000 samples of whole chickens bought from UK retail outlets and smaller independent stores and butchers. The two sets of results from quarter 1 and 2 (sampling period July to December 2015) are available.