- PURPOSE

This notice cancels and reissues the content of FSIS Notice 29-16 to provide clarification on the requirements of the final rule in Section III, the products that are not subject to new requirements in Section IV, and to fix the web-link to the final rule in Section II. This notice provides instructions to inspection program personnel (IPP) on how to verify that establishments meet the new labeling requirements for raw or partially cooked needle or blade tenderized  beef as specified in 9 CFR 317.2(e)(3).

beef as specified in 9 CFR 317.2(e)(3).

- BACKGROUND

On May 18, 2015, FSIS published a final rule to establish labeling requirements for raw or partially cooked mechanically tenderized beef products (Descriptive Designation of Needle- or Blade-Tenderized (Mechanically Tenderized) Beef Product (80 FR 28153)). The rule amends the regulations by adding 9 CFR 317.2(e)(3). See Section V. of this notice for the effective date for this rule.

III. REQUIREMENTS OF THE FINAL RULE

- Under 9CFR317.2(e)(3) the product name for a mechanically tenderized beef must contain a descriptive designation:

- “Mechanically Tenderized” or, if needle tenderized the product can be described as “Needle Tenderized,” or if blade tenderized, the product can be described as ”Blade Tenderized.”

- The product name and the descriptive designation must be printed in a single easy-to- read type style and color and must appear on a single-color contrasting background. The print may appear in upper and lower case letters, with the lower case letters not smaller than one-third (1/3) the size of the largest letter, and with no intervening text between the identity of the meat and the descriptive designation. The descriptive designation may be above, below, or next to the product name without intervening text or graphic on the principal display panel.

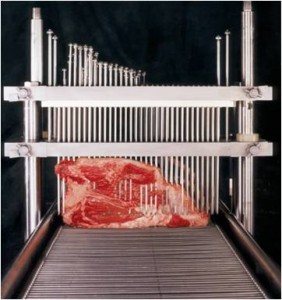

NOTE: See Attachment 1 for label examples.

DISTRIBUTION: Electronic NOTICE EXPIRES: 7/1/17 OPI: OPPD

- Products that are going to another official establishment to be fully cooked or to receive another full lethality treatment are not required to have the descriptive designation.

- Thelabelsofraworpartiallycookedneedle-orblade-tenderizedrawbeefproductsdestined for household consumers, hotels, restaurants, or similar institutions must bear validated cooking instructions (see Section VI, C.).

- PRODUCTS NOT SUBJECT TO THE REQUIREMENTS OF THIS FINAL RULE

- Non-intact beef products that are clearly non-intact, e.g., ground beef patties, hamburger patties, beef patties.

- Beef products that are tenderized by other than needle and blade, such as pounding or cubing, which visibly changes the appearance of the product, e.g., cubed beef steak.

- Any beef product that has been fully cooked and those destined to another Federal establishment to receive a full lethality treatment.

- Raw or partially cooked products labeled as “Corned Beef” that have been mechanically tenderized (including through injection of a solution).

- Raw mechanically tenderized beef products that are less than 1/8” thick, such as, beef bacon or carne asada, or raw mechanically tenderized beef products that are diced, such as stew meat.

- EFFECTIVE DATE

The final rule was effective for needle- and blade (mechanically) tenderized beef products on May 17, 2016. Product already labeled and in storage prior to the effective dates will not need to be relabeled prior to distribution.

- IPP RESPONSIBILITIES

- After the implementation date of this notice, IPP are to verify whether establishments meet the requirements in 9 CFR 317.2(e)(3) while conducting the General Labeling task in accordance with FSIS Directive 7221.1, Prior Labeling Approval. IPP are to determine whether the establishment produces this type of product by reviewing a copy of the final label that is in use, the product formulation, the processing procedure for the product.

- When performing the General Labeling task, IPP are to verify the required validated cooking instructions contain at a minimum the following information in order to comply with 9 CFR 317.2(e)(3)(iii):

- The cooking method (e.g., grill, bake);

- That these products need to be cooked to a specified minimum internal temperature;

- Whether these products need to be held for a specified time at that temperature or higher before consumption to ensure that potential pathogens are destroyed throughout the product; and

- A statement that the internal temperature should be measured by a thermometer.

NOTE: These validated cooking instructions may appear anywhere on the label.

NOTE: These validated cooking instructions may appear anywhere on the label.

2

- IPParetobeawarethatestablishmentsmaywishtoincludeadditionalinformationwithin the descriptive instructions that will make the labels more useful to consumers; however, FSIS will not require additional information on the product labels. For example, establishments may wish to include the temperature setting of the cooking device, time to complete cooking, whether the product needs to be flipped during cooking, the amount of time to cook on each side exposed to the heat source, recommendations to thaw the product, if applicable, or recommendations to measure the temperature in thickest part of the product, etc.

- WhenconductingtheHazardAnalysisVerificationTaskasdescribedinFSISDirective 5000.6, Performance of the Hazard Analysis Verification (HAV) Task for HACCP plans that include mechanically tenderized beef products subject to the Rule, IPP are to verify that the establishment has the appropriate supporting documentation to validate the cooking instructions provided on the label.

NOTE: If IPP have questions regarding the adequacy of the support, they are to seek guidance from their immediate supervisor or an Enforcement, Investigation, and Analysis Officer (EIAO).

- IPP are to document the results of their verification, including any noncompliance, in PHIS in a manner that accords with Chapter VI of FSIS PHIS FSIS Directive 7000.1, Verification of Non- Food Safety Consumer Protection Regulatory Requirements.